U-Weld-It Custom Steel Driveshaft Kit, 1350 Series, 3 Inch O.D.

- 3-inch OD 1020 DOM tubing with a 0.083-inch wall thickness

- Tubing length is 50 Inches and includes rear tube yolk welded on

- Maximum length as shipped is 55-inches center-to-center of U-joints

- Perfect for street rods, muscle, and kit cars up to 600 HP

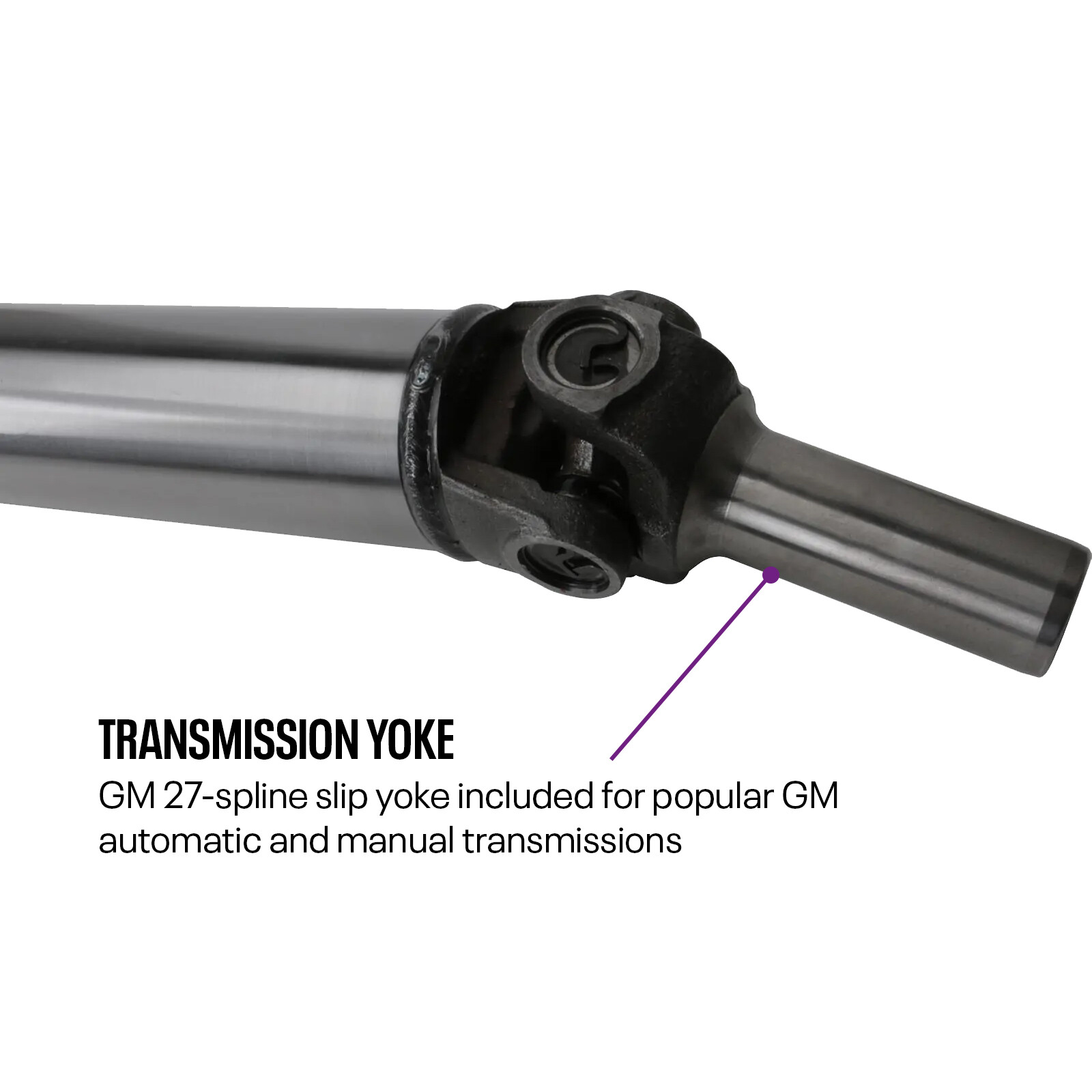

- Includes GM 27-spline slip yoke for popular GM transmissions

- Includes 1350 universal joints front and rear (rear preinstalled)

- Includes front tube yoke to be welded on by end user

- Driveshaft tube can be cut easily with chop saw or band saw

- Driveshaft MUST be balanced before on-road use

A Ready to Finish Driveshaft Right to Your Door

We have all been there. You just spent the weekend with a few friends dropping in that hot V-8 and your transmission of choice into your project’s rolling chassis. What is next? Connecting all that performance to your rear axle via a driveshaft.

However, your existing driveshaft (if you even have one) is likely 50 years old or is no longer correct for the new transmission and/or rear axle you have upgraded to. What to do? In the past you probably would have trailered your project to a driveshaft shop, dropped it off to have a custom driveshaft made, and picked it up several days later with a shiny new driveshaft installed.

While this certainly works, we know not everyone has a car trailer and something suitable to pull it with. Not to mention the thought of leaving your baby at some shop where it could possibly be damaged. Now, thanks to Speedway Motors’ new line of U-Weld-It steel drive shaft kits, you can assemble your project’s driveshaft at home with nothing more than a saw and a MIG welder. How much easier can it be than that?

Built with Steel for Strength and to Save You Money

There are a lot of great materials to make super strong driveshafts capable of high horsepower and we are often asked about an aluminum driveshaft vs carbon fiber. But we know most of our customers are going to be running a crate engine or custom build of 600 HP or less, and for the capability and value a steel driveshaft vs aluminum is the best answer.

Our driveshafts begin as 50-inch lengths of “driveshaft quality” 3-inch OD 1020 DOM tubing. We weld on the rear tube yoke and fit the rear 1350 universal joint in place so all you must do is determine the correct overall length your project vehicle needs, cut the tubing to length, weld on the front tube yoke, and finish the driveshaft with the included 1350 front U-joint and slip yoke pieces. Even if you do not have everything you need to finish the driveshaft yourself you will still be steps ahead having a local driveshaft shop finish weld the front tube yoke and balance the shaft for you.

The Perfect Alternative

These U-Weld-It kits bridge the gap between expensive pre-finished driveshafts and having to deal with dragging your project car to a driveshaft shop. Now you can handle most of the measuring, labor, and assembly right in your own garage. Our 1350 universal joint model covers a large majority of drivetrain combinations out there, but if your application uses a 1310 series universal joint then you will want to look at our . Order your U-Weld-It steel driveshaft kit today and keep your custom driveshaft cost in check!

Driveshaft MUST be balanced before on-road use

I would buy this product again without hesitation

Summary: Perfect for my transmission change, upgraded my 71 Firebird from Th350 to 2004R transmission with a Moser rear end and needed an updated driveshaft with correct size U joints, This works perfectly and I can choose the desired length of driveshaft according to my application.

Pros: Good packaging Good price, fast international delivery

Yes, I recommend this product.