| MODEL | SDSJ-2 |

| Input Power | AC220V 50/60HZ |

| Working model | Spot,continuous,argon arc |

| Data storage | 20 group |

| Power | Less than 15W |

| Volume | 225*145*190mm |

| Weight | 2.9KG |

Product specification

Machine parameters:

Product Type: SDSJ-2

Frequency: 50Hz 60Hz

Applicable: 99.9% argon arc welder upgrade

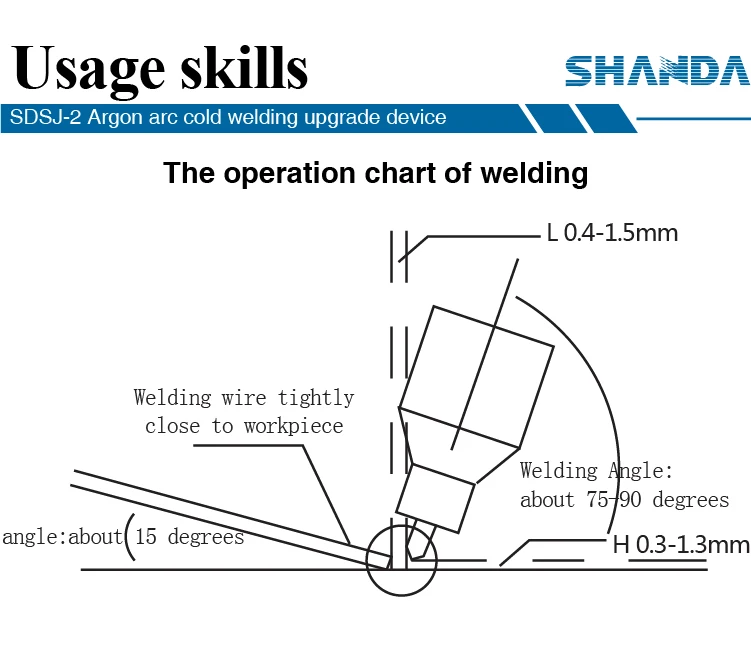

Time mode: Welding time: 1-999mS

Interval time: 1-999mS

Data storage: 20 groups

Input power: single phase 220V ± 20%, 50Hz

Power: less than 15W

Host area of about: 225 * 143 * 190mm

Host Weight: 2.9 kg

Frequency mode: pulse frequency: 1-20Hz

Pulse accounting hole: 1-99%

Working mode: spot welding, welding, argon arc welding

Accessories list: host, power cable, installation line, manual

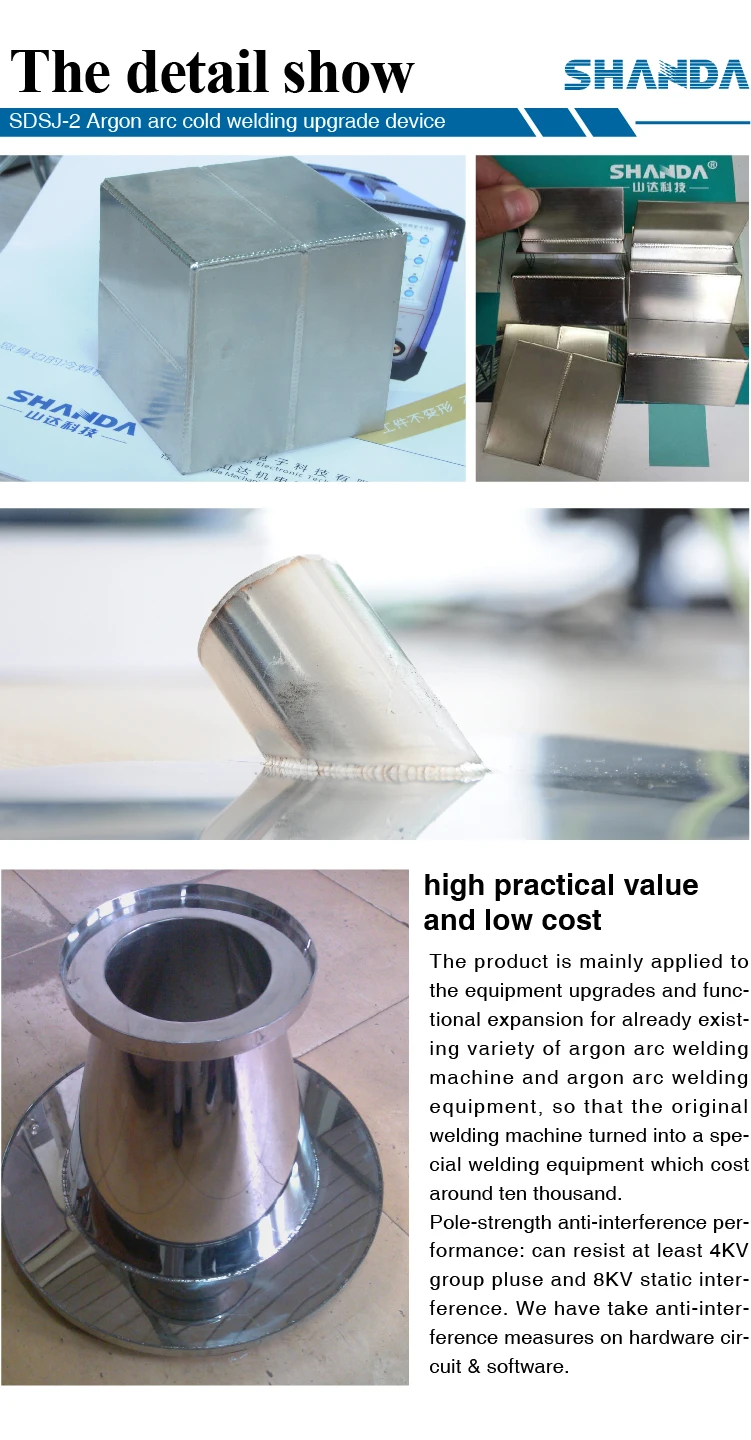

Area of application:

First, the mold industry

1, injection mold 2, stamping die 3, die casting mold 4, rubber mold 5, copper alloy die

After welding the mold can be a variety of mechanical processing, heat treatment and nitrusion

Second. The foundry industry

In the casting process, pores and shrinkage etc. can be fast and accurate repair

Ductile iron, gray iron, stainless steel and other defects of the excellent repair effect,

Welding speed, welding without color or color difference is small, suitable for factory scale production needs.

Third, all kinds of industry repair parts

The machine for shaft, teeth and other work pieces can be the perfect repair

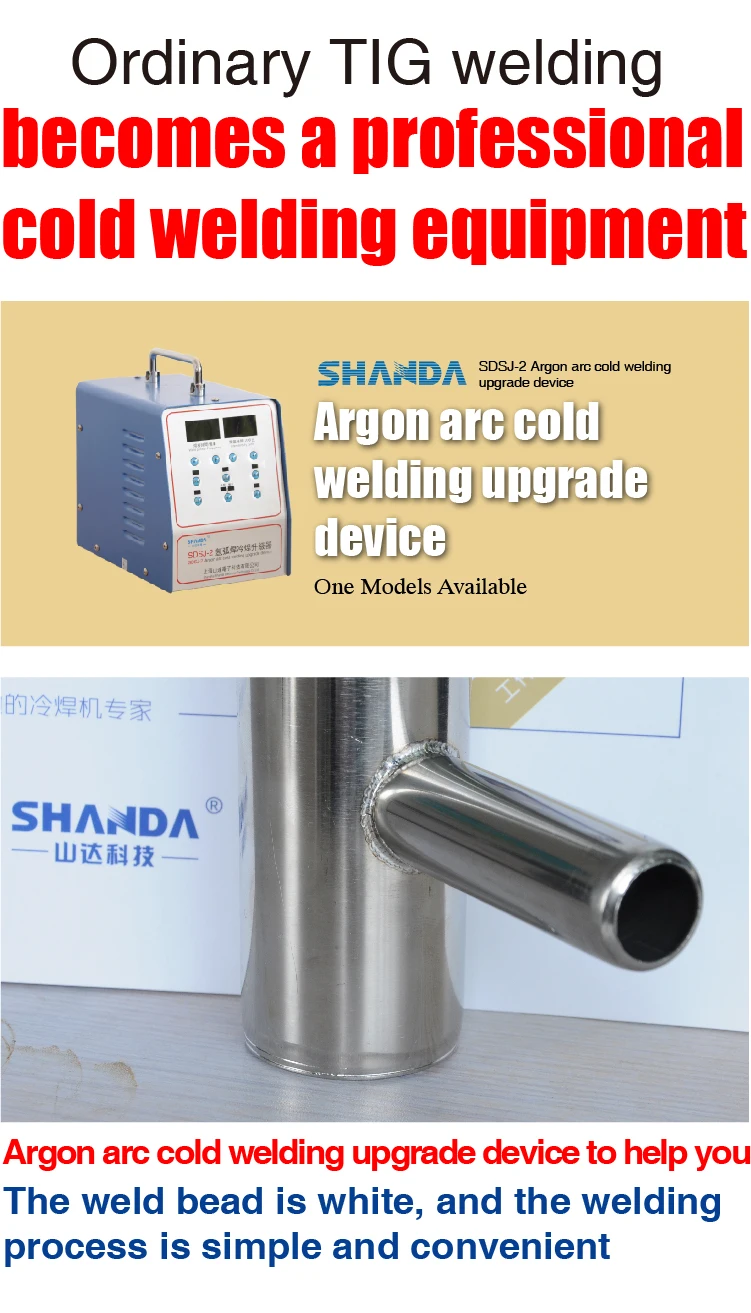

SDSJ-2 argon arc welding improved use of cold welding:

Installation is simple and convenient, no need to disassemble, directly to the adapter cable of the machine can access the argon arc welding machine interface switch can be, Matching with most arc welding machine argon (support MOS and IGBT), so basically no need to confirm your welder, If it is multi-function, if it comes with pulse, delay, spread air and other functions, they are applicable to this machine, as long as your welding machine and parameters machine to adjust (parameter setting method, refer to manual) Parameters after connection According to the normal welding method can be used, Can achieve the effect of cold welding.