HITBOX AC DC TIG 200A IGBT TIG MMA Inverter Welder

The control technology is suitable for various applications and significantly improves welding performance.

1. TIG (Tungsten Inert Gas) – gas shielded welding with inert/inactive gases such as argon 4.6 (99.996%). The glowing, non-consumable tungsten electrode melts the workpiece and allows the addition of the filler metal that forms the weld.

2. MMA (MMA) stick welding / ARC welding – a universal welding process. An arc melts the electrode, thus forming the weld. No shielding gas is required.

3. Note: This device is not intended for use in residential areas supplied by a public low-voltage power supply system. Ensuring electromagnetic compatibility in these areas may be difficult due to both conducted and radiated interference.

Why choose HZXVOGEN 110V/220V 200Amp TIG Welder Machine?

- Dual Voltage, 200A Output:Our AC TIG welder supports both 110V and 220V power supplies, allowing you to work in various environments. With a maximum output current of 200A, this welder delivers high voltage and high current, ensuring rock-solid welding stability and superior performance every time

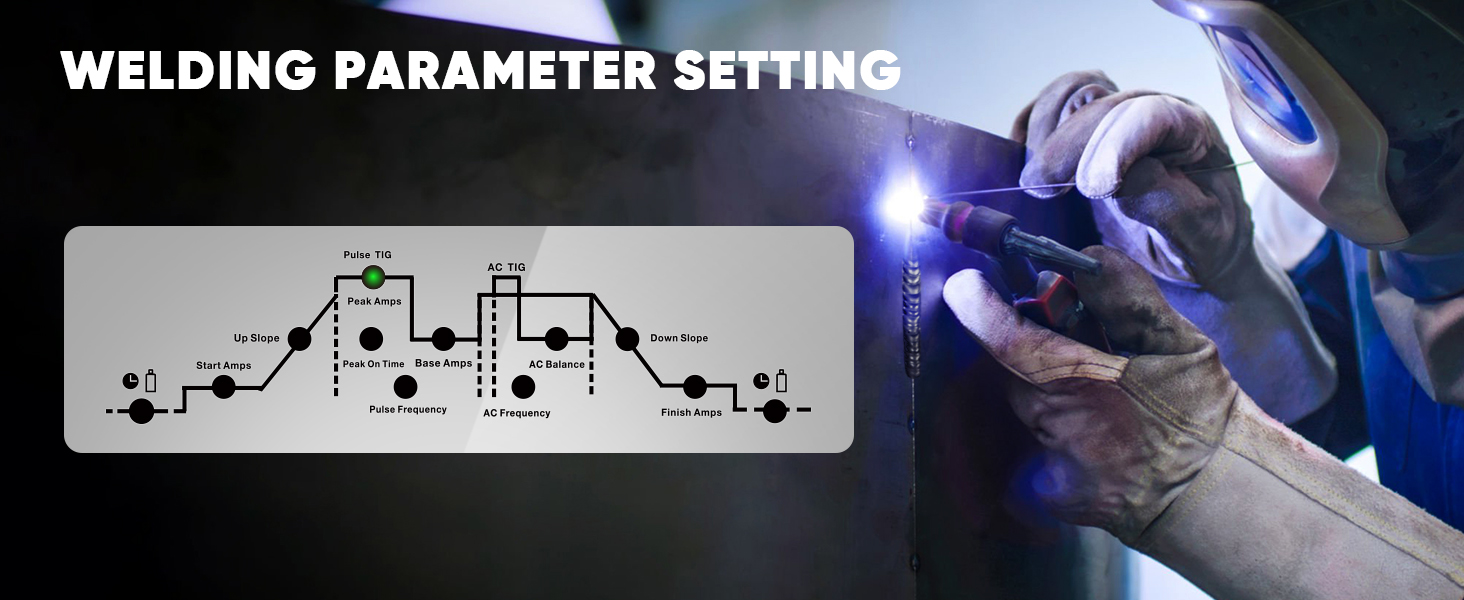

- Easy to Operate: The HVT250PP Aluminum welding machine is designed with user-friendliness in mind. You can effortlessly set pre-gas time, start current, uphill time, peak current, AC frequency, pulse frequency, downhill time, and after-gas time. These friendly settings allow you to create clean, high-quality welds with minimal post-weld cleaning, saving you time and effort

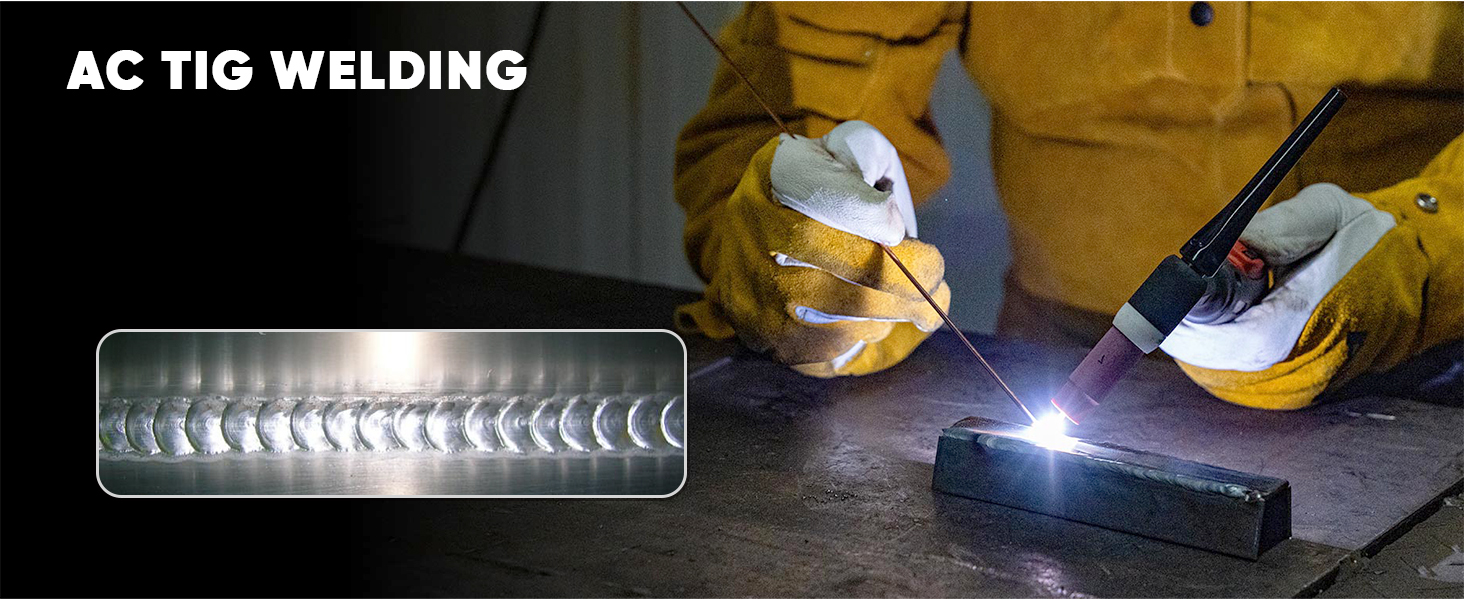

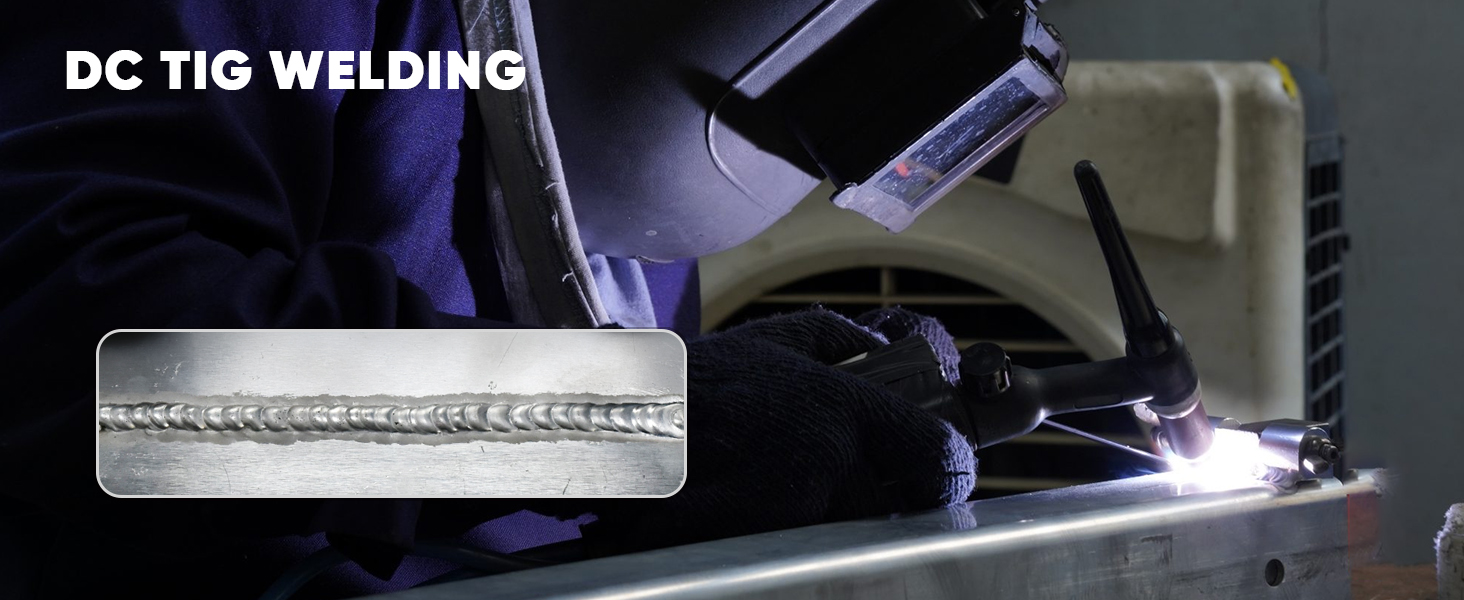

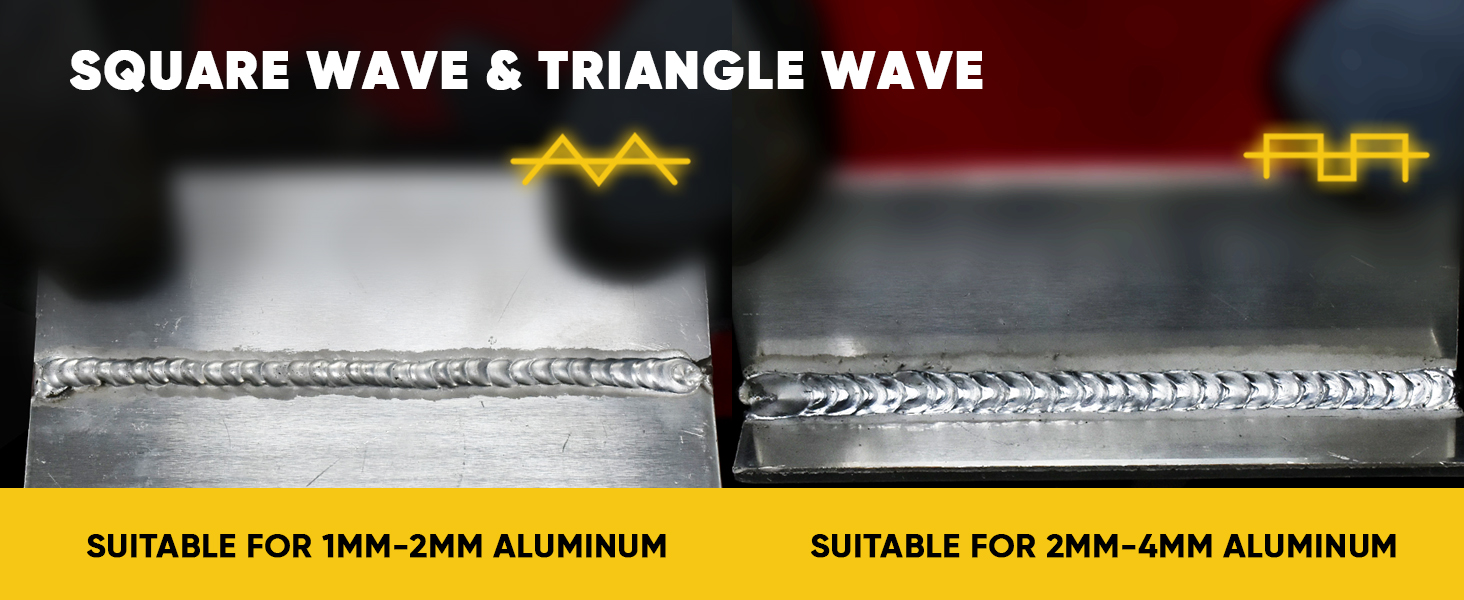

- Advantage of Materials:When you use dc current, it produces a more stable arc and less spatter, suitable for carbon steel, stainless steel, low alloy steel and copper and so on. AC welding is more versatile when welding specific and exotic metals such as aluminum and specific alloys,the alternating current helps break through surface impurities

- Advanced Features: Our welder offers advanced 2T and 4T modes to suit your welding style. In 2T mode, high-frequency ignition remains active until you release the button on the torch, providing continuous control. In 4T mode, the arc ignites with a single press and release, and terminates with another press and release, giving you precise control over your welding process

- Safety Systems: Our AC TIG welders are equipped with VRD (Voltage Reduction Device), over-voltage, over-current, overload, and overheat protections. Additionally, the unique cooling system rapidly dissipates heat, extending your welding time and ensuring a stable, high-performance TIG weld

- Machine Weight: 33.6LBS/16.8KG, Machine Size: 17.3 x 13.3 x 6.2inch

Device Functions & Components

AC/DC TIG welding – alternating current (AC) and direct current (DC). Welding of almost all metals, such as steel, stainless steel, aluminum, copper, and much more.

2-in-1 combination device – TIG & MMA welding is possible up to 200A.

IGBT technology – The latest and most modern transistor technology enables high-performance welding! No transformer, no MOSFET, just the latest IGBT!

Lightweight & compact design – at only 10 kg, the device is ideal for versatile welding applications. Innovative IGBT transistors save space and weight compared to older MOSFET technology. No more heavy lifting!

HF ignition – enables contactless ignition and ensures significantly better welding results. No lift arc, no strike ignition!

Highest efficiency & performance – Single-phase alternating current (230V) supplies the device and allows an output of true 200 amps.

Smart Cooling & Overheating Protection – State-of-the-art technology, integrated overheating protection, and high-performance cooling enable maximum performance.

2T/4T (TIG) – determines the operating mode and offers extended control over the current flow. In 2T mode, high-frequency (HF) ignition remains active until the torch trigger is released. In 4T mode, the arc is ignited after pressing and releasing the trigger once. Pressing and releasing it again stops the ignition. Some functions, such as current reduction, are only available in 4T mode.

Current reduction – prevents the formation of blowholes (end craters) at the end of the weld.

Gas pre- and post-gas flow (TIG) – protect the tungsten electrode from excessive wear and protect the weld from oxidation. These parameters can be individually and separately adjusted. They specify how long gas should flow before and after ignition.

Specification: