20mm Dia Single Extruder Screw, 300mm Length Barrel and 1.75mm or 2.5mm Nozzle

for DIY Desktop Plastic Extruders Machine

Package contains:

1x 290mm Length Drilled Barrel with 1x 2.5mm/1.75mm Nozzle

3x 220V 150W D40L40 Regular Mica Band Heaters

3x K-Type 0.5meter M6 Thread Thermocouples.

Technical Parameters:

Productivity: 0.1~0.5kg/h,20g per shot

Suit for HDPE, LDPE, LLDPE, PVC, PP, glass fiber, PPS, PPA and other special plastic recycling.

Maximum rotation speed: 60RPM

Maximum heating temperature: 450℃

Bimetallic layer depth: 3 mm

Bimetallic hardness: 57~69HRC

Hard-chrome plating hardness after nitriding: ≥950HV

Chrome-plating layer depth: 0.03-0.09mm

Surface roughness: Ra 0.4

Compression Ratios: 20mm extrusion screw is 2.8

Technical Information:

Main Base materials

1.38CrMoAlA (SACM645)

2.SKD-61 (Special Tool Steel)

3.42CrMo (Ultrahigh Strength Steel)

4.DC53 (Cold Work Die Steel)

5.W6Mo5Cr4V2 (High-Speed Tool Steel)

Processing Techniques

1. Heat treatment

2. Quenching

3. Bimetallic alloy welding for screw

4. Bimetallic alloy centrifugal casting for barrel

5. Hard-chrome electroplating

6. Linearity of screw:0.015mm

Drawing:

CAD files are available.

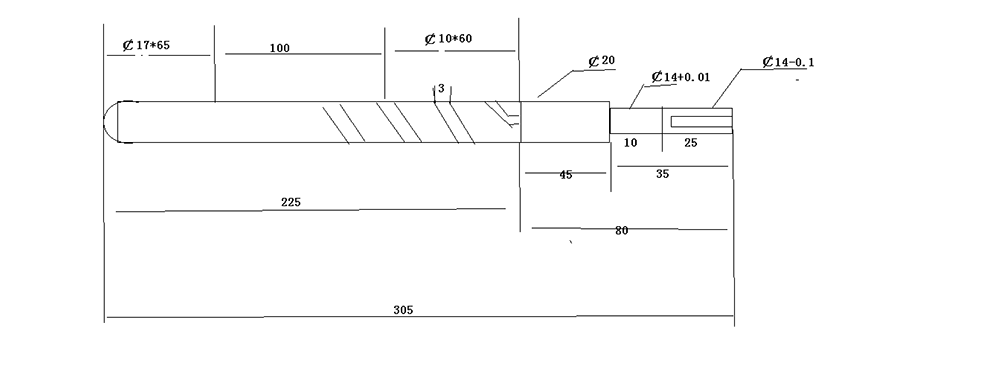

Screw:

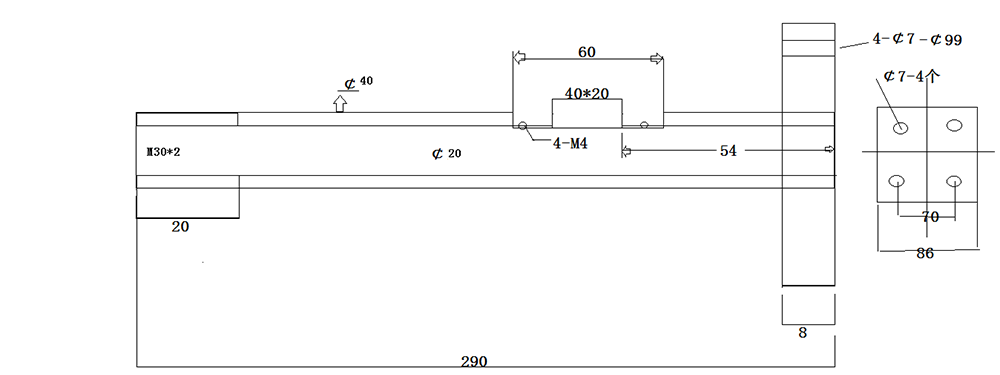

Barrel:

FAQs:

Q: What is the recommended speed for the screw?

A: About 21~35 rpm.

Q: The material of screw, barrel & nozzle?

A: The screw is made of SKD61 vacuum quenching, barrel is 38CrMoAlA nitrided

and the nozzle is carbon steel.

Q: What the difference between Stainless steel Mica heaters and Brass ones?

A: The Brass heaters have the advantages of faster heat transferring, higher wear of resistance and longer service life.