Each high quality chuck comes with a certification that documents TIR.

Product Code

202-5410+202-6107-6

Product description

Lathe chuck:

- Diameter: 4''

- Thickness: 2.16''

- Center Hole: .87''

- Bolt Circle Diameter: 3.307''

- Runout: 0.003''

- Max. Input Torque: 60 Nm

Back plate:

- Mounting Thread Size T: 1- 10 TPI

- Shoulder Diameter D1: 2.87"

- Bolt Circle Diameter D2: 3.307"

- Hub Length C: 0.393''

- E: 0.5"

- Hub Diameter D: 2.2''

- Flange Thickness B: 0.63''

- Shoulder boss h: 0.1''

- No. of Bolt Holes: 6

Product application

Fully machined back plate can be mounted onto our 4" 3 jaw or 4 jaw self centering and independent lathe chuck (p/n 202-5410, 202-5472, 202-5419).

You would not need to drill any mounting holes but you will need to turn the shoulder down .050" to match the back of the lathe chuck to make the chuck & back plate more concentric with the lathe spindle. When turning the shoulder of the backing plate, ONLY TURN THE SHOULDER OF THE BACKING PLATE WHEN ATTACHED TO THE LATHE SPINDLE. If you use a chuck to clamp the backing plate and then turn it, the backing plate will not be true to the lathe spindle and will have more runout than specified when the chuck and back plate are put together.

Product features

A matching back plate (sold separately) would need to be machined on the face and hub OD in order to fit this chuck. For detailed information, please look for the Shars back plate machining guide.

Semi-steel chuck body made from high quality cast iron

- Each pinion is ground and hardened to HRC 43

- Both sides of the jaw teeth and guides are ground and hardened to HRC 58-62

- Each set of jaws are serialized in their own set

- A serialized set of jaws are then finished, ground, and lapped on their designated chuck body which will be the same chuck body on the final assembly to achieve a greater accuracy

- Before assembling the jaws to its designated chuck body, the jaws finish machining is performed on a close tolerance state of the art CNC machine from Japan

- The scroll plate's thread flank are ground on both sides to achieve tighter contact with the master jaw

- Each chuck has gone through rigorous accuracy and repeatability inspection by clamping and jamming multiple random testing rods or rings

- Accuracy is maintained for the entire clamping range

- Internal Jaw:

- Clamping Range A-A1: 0.078-1.181"

- Jamming Range B-B1: 1.181-3.543"

- External Jaw

- Clamping Range C-C1: 1.181-3.150"

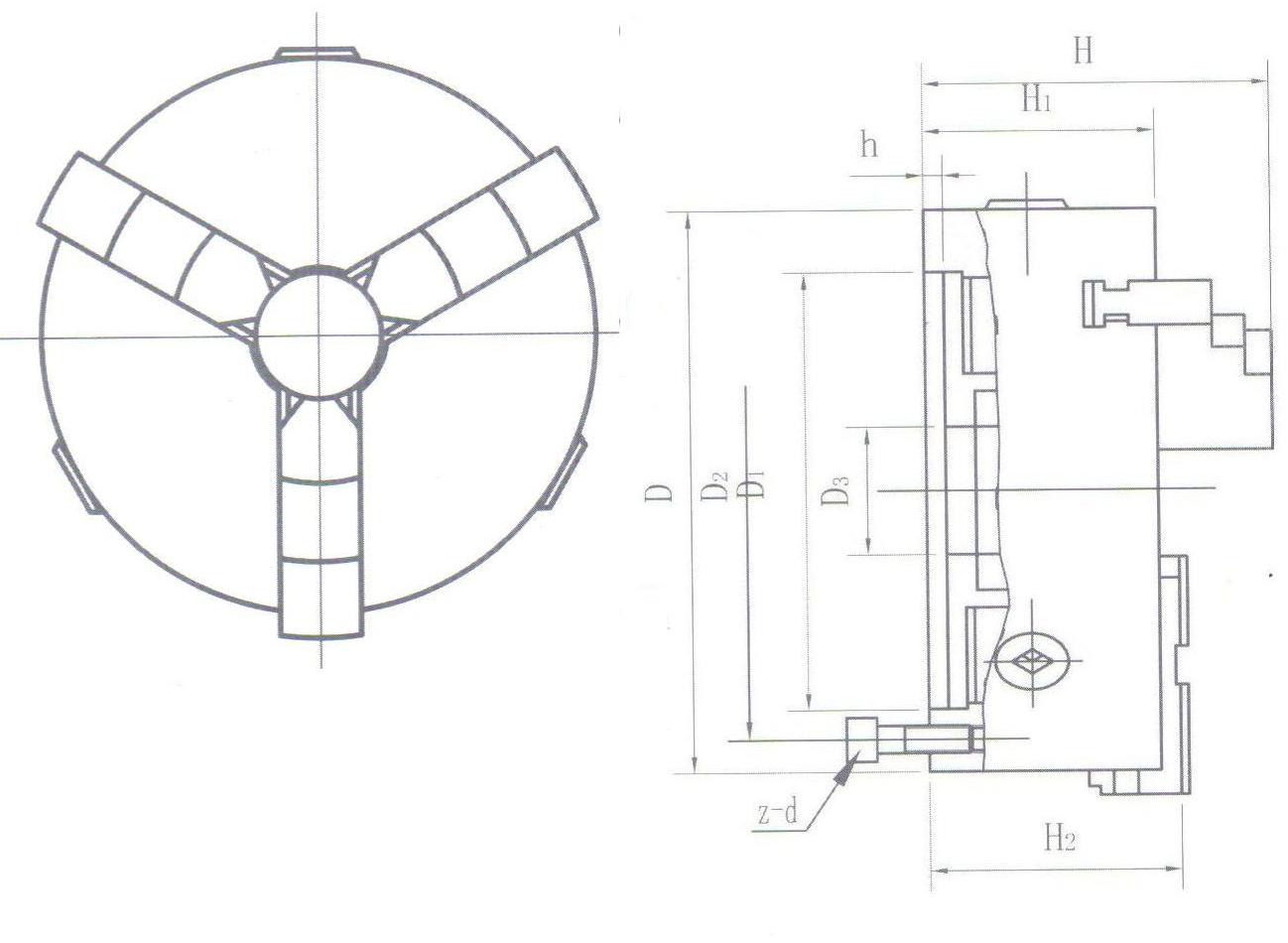

| Size (inch) | D (inch) | D1 (inch) | D2 bolt hole circle dia. (inch) | D3 (inch) | H (inch) | H1 (inch) | H2 (inch) | h (inch) | z-d (metric) |

| 4 | 3.937 | 2.835 | 3.307 | 0.866 | 2.933 | 2.165 | - | 0.118 | 3M-8 |

- Fully machined back plate can be mounted onto our 4" 3 jaw or 4 jaw self centering and independent lathe chuck (p/n 202-5410, 202-5472, 202-5419). Shoulder will have to be turned to true chuck up to your lathe.

- Made from high grade cast iron

- Fits most 4" self centering and independent plain back chuck (please verify the bolt circle diameter and shoulder diameter on the back of the lathe chuck)

- 2 set of hard solid jaws: inside jaw set and outside jaw set

- 3 piece of mounting screws for the lathe chuck back plate

- 1 hexagon wrench

- 1 piece of fully- machined back plate

How to process back plate to guarantee Chuck's T.I.R?

Fully machined back plate can be mounted onto 4"3 jaw or 4 jaw self centering and independent lathe chuck (p/n 202-5410, 202-5472,202-5600, 202-5419). As long as back plate Shoulder Diameter 2.87"> chuck's D1, all 4" chuck will fit in. All back plates have 0.04" allowance, please measure the size of Chuck's D1 before process your back plates. The size of back plates's D1 should be a little bit smaller than the size of Chuck's D1. Because the gap between back plate and chuck is smaller, chuck's TIR is better. No gap is the best. D1 need to be processed before back plate can be mounted.

You would not need to drill any mounting holes but you will need to turn the shoulder down .040" to match the back of the lathe chuck to make the chuck & back plate more concentric with the lathe spindle. When turning the shoulder of the backing plate, ONLY TURN THE SHOULDER OF THE BACKING PLATE WHEN ATTACHED TO THE LATHE SPINDLE. If you use a chuck to clamp the backing plate and then turn it, the backing plate will not be true to the lathe spindle and will have more runout than specified when the chuck and back plate are put together.

- The back plate may come with two or three additional screws (depending on type) for removal the back plate from the chuck. They are not used to mount the chuck to the back plate, mounting screws should be included with the chuck

Lathe Lathe Chuck Diameter

| BRAND |

MODEL |

SWING |

SPINDEL THREAD |

3" |

4" |

5" |

6" |

|---|---|---|---|---|---|---|---|

| ATLAS | 6" | 1/2"-20 | 202-6231 | ||||

| ATLAS | 10100 | 6" | 1"-10 | 202-6107-6, 202-6107-3 | |||

| ATLAS | TH42 | 10" | 1 1/2"-8 | 202-6230 | 202-6108-6, 202-6108-3 | 202-6192 | 202-9106, 202-6119 |

| ATLAS | 5991 | 12" | 1 1/2"-8 | 202-6230 | 202-6108-6, 202-9108-3 | 202-6192 | 202-6109, 202-6119 |

| ATLAS | 3986 | 12" | 1 1/2"-8 | 202-6230 | 202-6108-6, 202-6108-3 | 202-6192 | 202-6109, 202-6119 |

| EMCO MAIER | MAXIMAT V10 | 5" | M39X4MM | 202-6214 | 202-6215, 202-6217 | ||

| GRIZZLY | G8688 | 7" | 3" FLANGE | ||||

| GRIZZLY | G4000 | 9" | M39X4MM | 202-6214 | 202-6215, 202-6217 | ||

| HARBOR FREIGHT | 33684 | 7" |