|

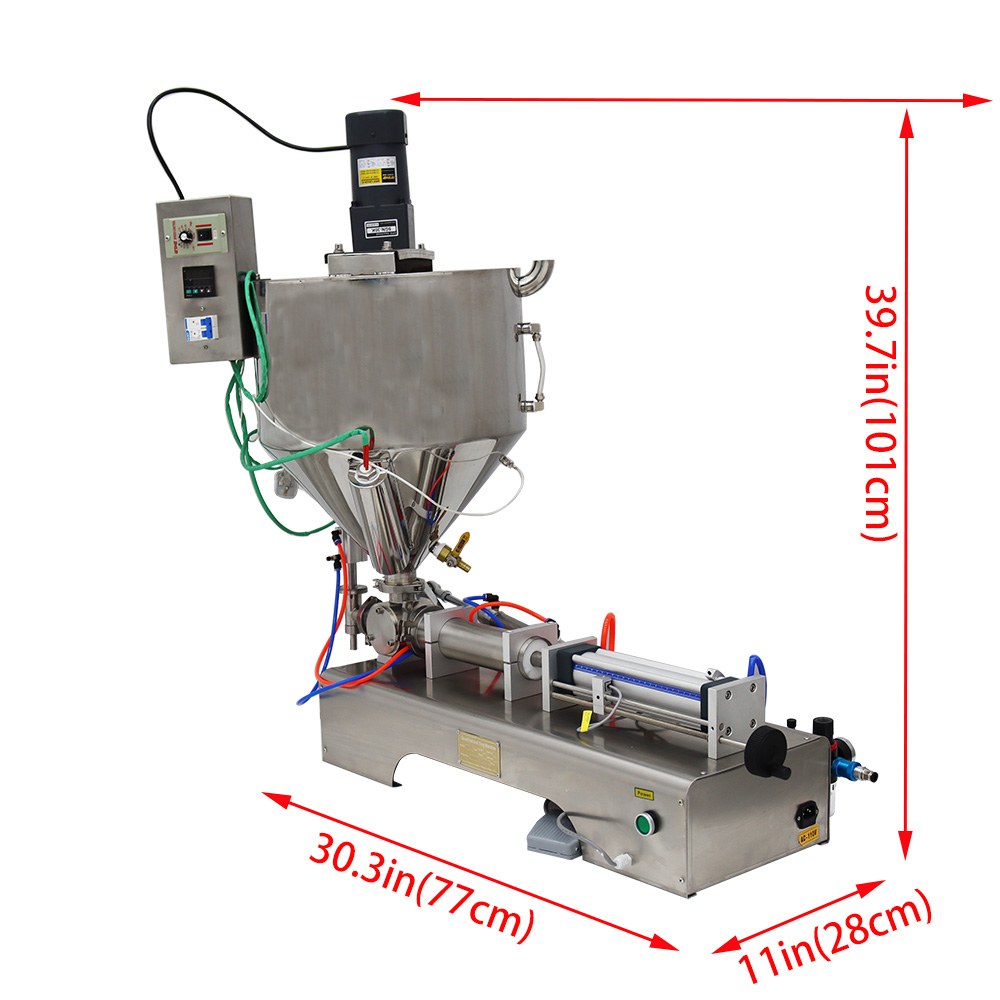

110V Paste Liquid Heating Stirring Filling Machine Please fill water or conduction oil in the interlay ! Need to work with air compressor !

The filling volume range is between 30ml - 300ml. And the machine should connect air compressor for working. First time when you use the machine, you should weigh the weight of output by adjusting and make sure the volume you want. Heating and Stirring Filling

Machine |

|||||||||||||||||||||

|

Product parameter:

Product analysis: |

|||||||||||||||||||||

|

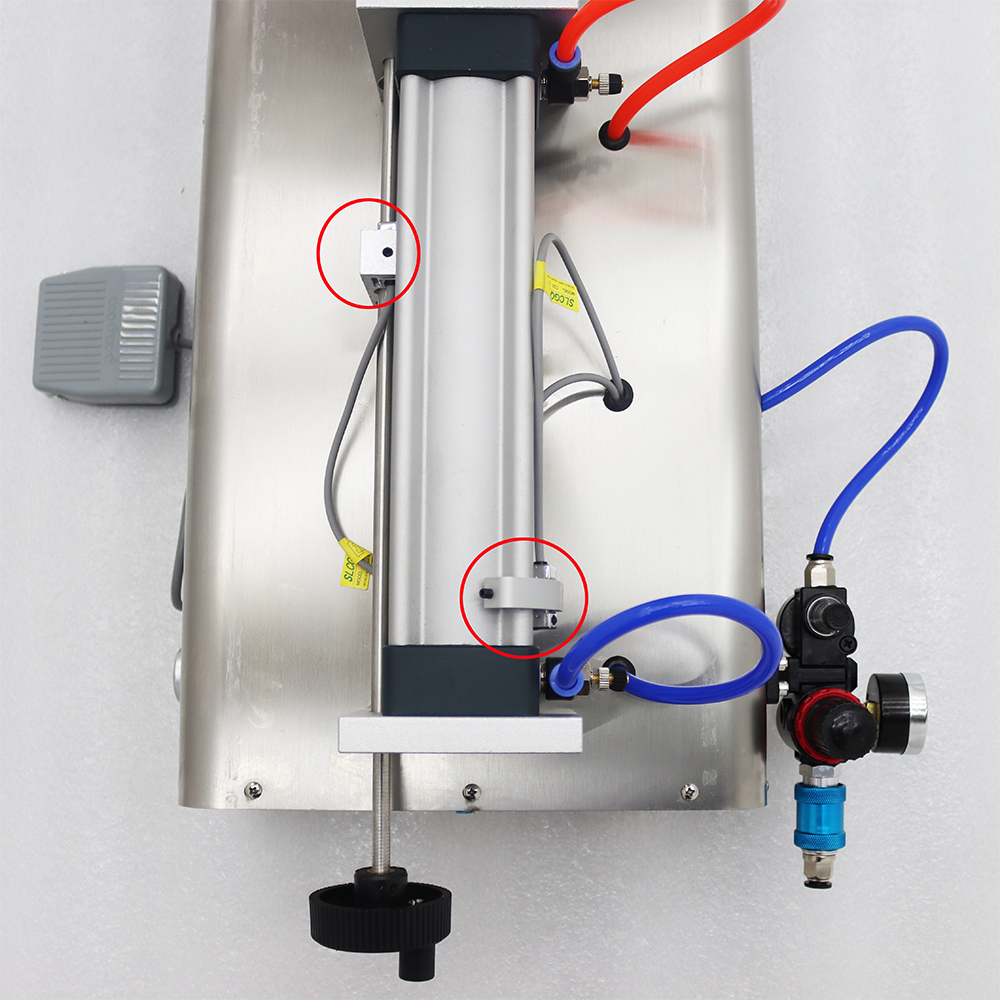

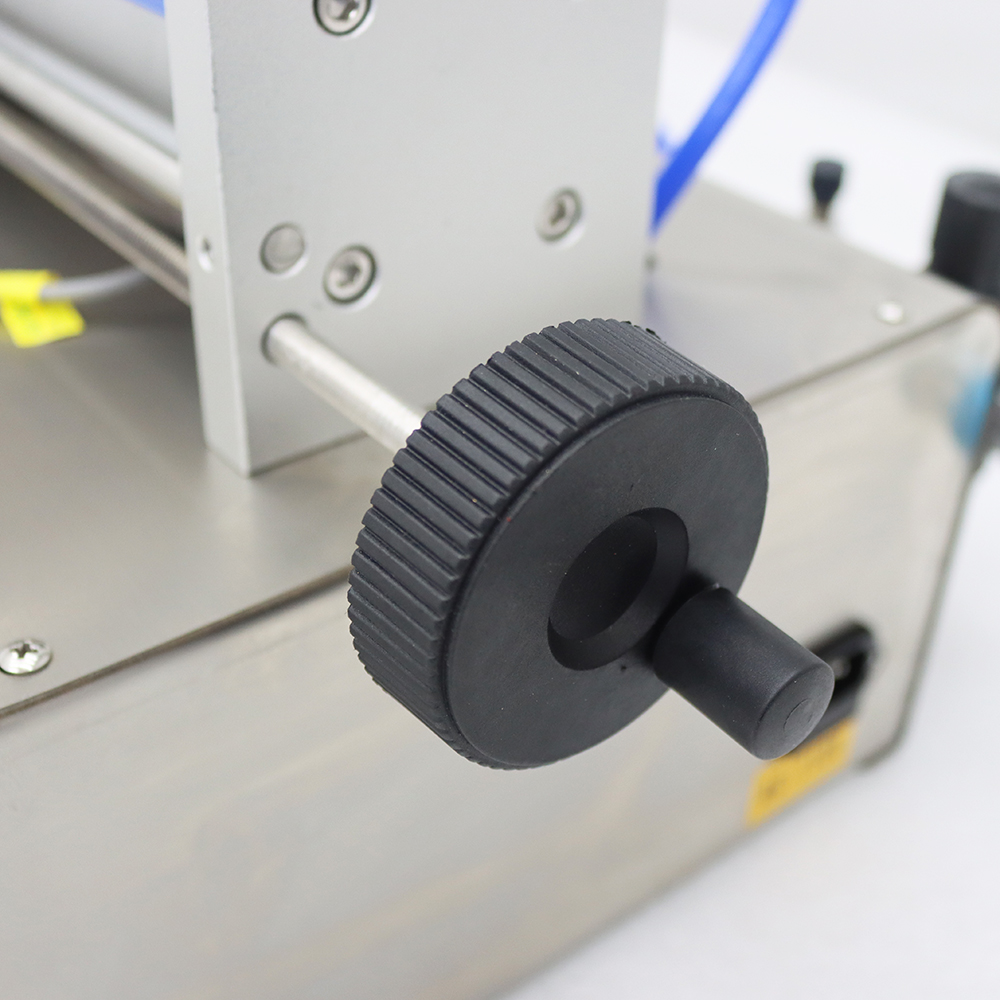

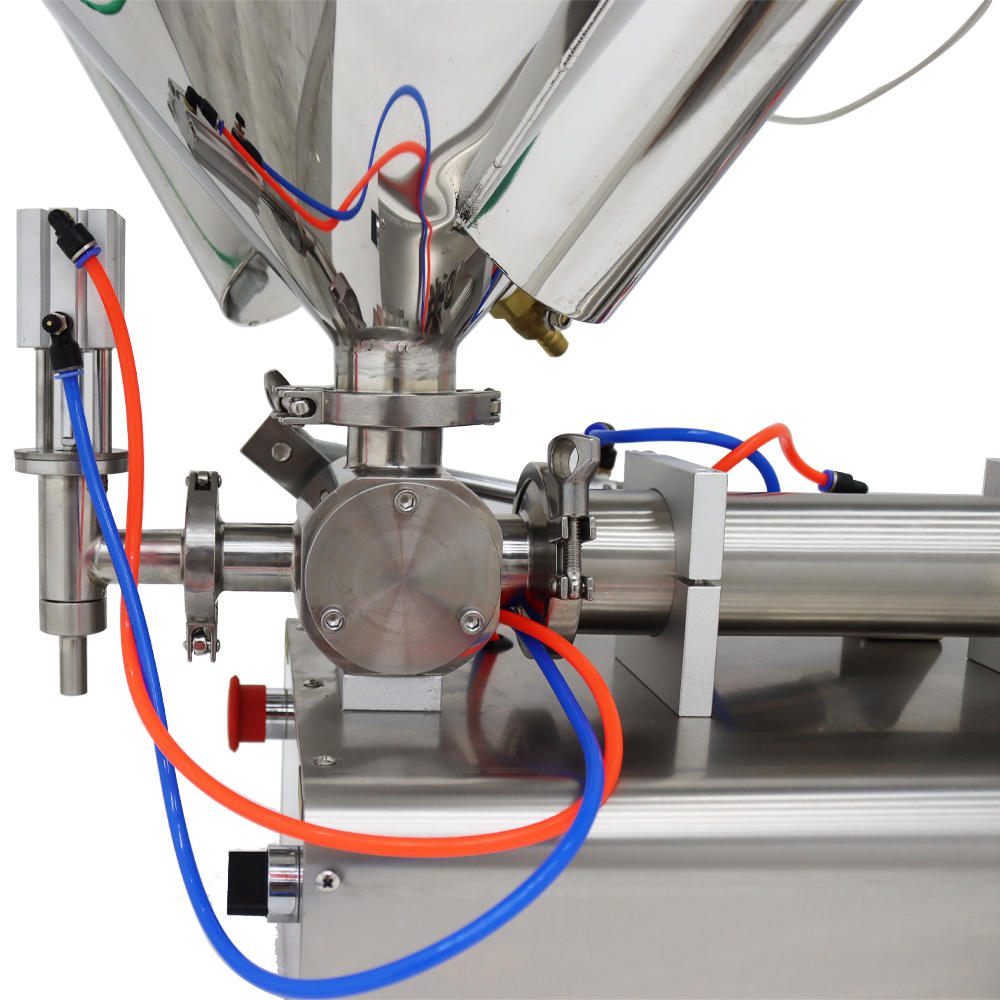

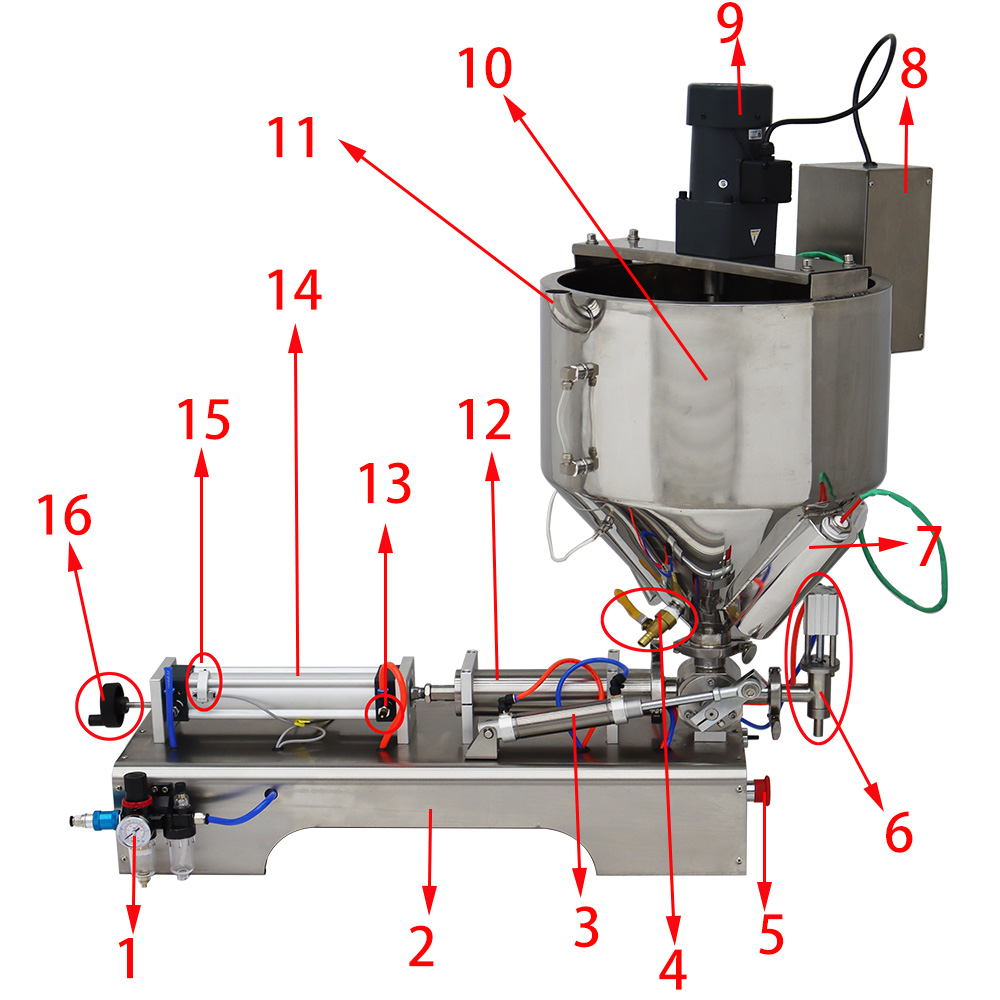

1.Pressure gauge assembly 2.Stainless steel body 3.Small cylinder 4.Water outlet 5.Emergency stop switch 6.Discharge assembly 7.Heating rod 8.Heating controller 9.Mixing motor 10.Heating and stirring double layer hopper 11.Water injection port (inlet for adding hot oil or water) 12.Stainless steel hopper 13.Filling speed adjustment knob 14.cylinder 15.Magnetic switch 16.Quantitative hand wheel |

||||||||||||||||||||

| Feature:

|

|||||||||||||||||||||

|

Note: 1.Our heating temperature controller itself has no limit on the adjustable range, but when applied to the hopper, the adjustable range is 0-118 degrees Celsius (different media have different maximum temperatures)! 2.We only sell machines, do not match air

compressors, customers need to buy their own.) Product safety precautions: This series of filling machine is only

suitable for filling liquid, low concentration paste . 1. Use a power supply and air source that conforms to the requirements of this machine . The stability of the air source must be maintained under continuous working conditions. 2. Before disassembling, washing or repairing this machine, please be sure to turn off the air source and power supply first. 3. The rear half of the machine (near the control buttons) and the lower part of the machine frame are equipped with electrical control components. Under no circumstances should the body be washed directly with water, otherwise there will be danger of electric shock and damage to the electrical control components. 4. After the power switch is turned off, there is still voltage in some circuits in the electrical control of this machine. When repairing the control circuit, please be sure to unplug the power cord. 5. Do not keep your eyes close to the filling head during work, pay attention to personal safety. 6. Do not put your hand on the central axis of the cylinder during the work process, pay attention to pinching your hands. 7. Before using materials for filling, it is best to clean the machine with detergent first, and then clean it with clean water, so as to avoid oil stains or foreign materials and materials mixing, which will lead to waste of materials and damage to the machine. |

|||||||||||||||||||||

| Item Number: 160439 | |||||||||||||||||||||

On Sep 23, 2024 at 23:10:01 PDT, seller added the following information: